Approach

The BioFoundry at UBC utilizes metabolic & enzyme engineering to investigate and customize novel biosynthetic enzymes that can convert biomass-derived feedstocks into better fuels, pharmaceuticals and value-added chemicals. We also extend these principles to the design and development of unique bioremediation strategies to rehabilitate the water quality in and around industrial zones and new mining technologies. In addition to green engineering, the BioFoundry also pursues medical biotechnology research, and we are working extensively on infectious disease drug discovery, drug delivery and tissue engineering.

Moreover, Prof. Yadav is an enthusiastic proponent of application-oriented science and knowledge translation for development of low-cost technologies, and the BioFoundry actively collaborates with local start-ups, industry, academic groups and medical research laboratories. Our work is fostering innovation in a strategic domain for Canada.

Themes

Synthetic biology and metabolic engineering are principal activities in the lab and we are actively working on fundamental and applied problems in terpenoid and polyketide biosynthesis and lignin valorization. We employ a combination of metagenomics-aided enzyme discovery, rational enzyme engineering, and pathway and genome engineering strategies to engineer strains that produce value-added molecules at higher titres and productivities, and actively collaborate with companies such as Phytonix Corporation and InMed Pharmaceuticals to commercialize these biotechnologies.

Synthetic biology and metabolic engineering are principal activities in the lab and we are actively working on fundamental and applied problems in terpenoid and polyketide biosynthesis and lignin valorization. We employ a combination of metagenomics-aided enzyme discovery, rational enzyme engineering, and pathway and genome engineering strategies to engineer strains that produce value-added molecules at higher titres and productivities, and actively collaborate with companies such as Phytonix Corporation and InMed Pharmaceuticals to commercialize these biotechnologies.

Read more: Revving the engine of biology to solve complex problems

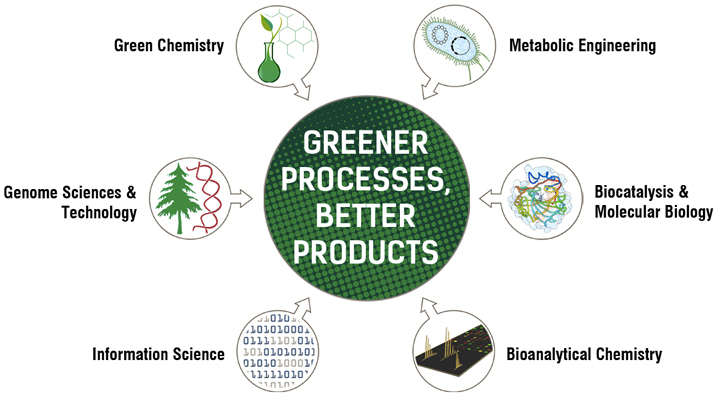

A warming world, the threat of epidemics, our rapidly declining drug stocks, and the inefficiency of current manufacturing processes have forced the industry to reconfigure its operations along the principles of Green Chemistry & Engineering. The new paradigm emphasizes improvements in the atom and energy efficiencies, and the environmental footprint of manufacturing processes by minimizing the generation of waste, eliminating the use of toxic reagents and solvents, utilizing renewable feedstocks, designing biodegradable products, and designing processes that minimize the likelihood of accidents. To this end, we are exploiting the immense ease and efficiency with which biological systems metabolize feedstocks to extract natural resources or produce value-added chemicals and materials to design and develop replacements for traditional chemical manufacturing processes.

A warming world, the threat of epidemics, our rapidly declining drug stocks, and the inefficiency of current manufacturing processes have forced the industry to reconfigure its operations along the principles of Green Chemistry & Engineering. The new paradigm emphasizes improvements in the atom and energy efficiencies, and the environmental footprint of manufacturing processes by minimizing the generation of waste, eliminating the use of toxic reagents and solvents, utilizing renewable feedstocks, designing biodegradable products, and designing processes that minimize the likelihood of accidents. To this end, we are exploiting the immense ease and efficiency with which biological systems metabolize feedstocks to extract natural resources or produce value-added chemicals and materials to design and develop replacements for traditional chemical manufacturing processes.

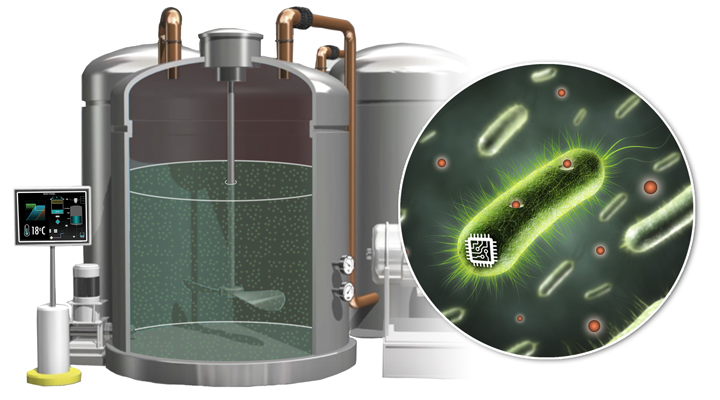

Our work in biomining addresses one of the most formidable challenges facing the mining industry – the extraction and processing of low-grade, hard-to-access ores. We are working with the Bradshaw Research Initiative for Minerals and Mining and other commercial partners to engineer synthetic microbial consortia to leach copper in packed bed reactors and subsequently deposit the metal in a carbon-neutral microbial fuel cell.

Similarly, we are developing innovative cyclic bioprocesses that utilize waste streams from chemical manufacturing processes as inputs to produce performance chemicals that valorize existing products or can be sold as value-added products themselves. We are currently demonstrating this concept by harnessing the metagenome of pulp and paper sludge to synthesize polymers for the production of performance paper.

We are also actively working on developing novel genetic circuits to bridge macroscopic bioprocess control with intracellular control of metabolism. These methods can deliver significant improvements in productivity.

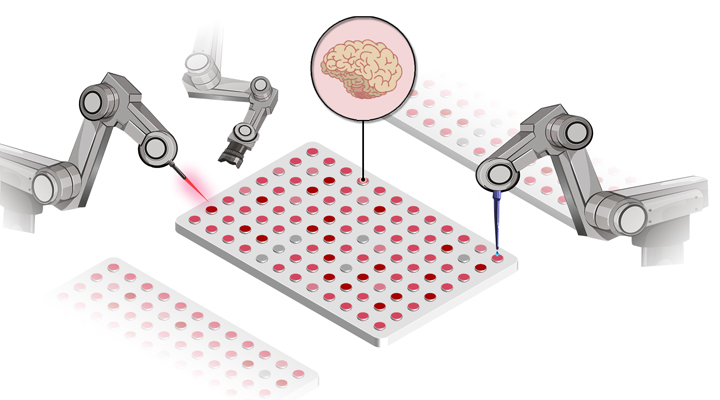

Our work on bioengineered assays is currently centred on two domains. The first project, undertaken in Our work on bioengineered assays is currently centred on two domains. The first project, undertaken in collaboration with STEMCELL Technologies and Precision NanoSystems, seeks to assemble three-dimensional, structured brain organoids from human induced pluripotent stem cells for use in pre-clinical screening of hits against neurodegenerative diseases.

Our work on bioengineered assays is currently centred on two domains. The first project, undertaken in Our work on bioengineered assays is currently centred on two domains. The first project, undertaken in collaboration with STEMCELL Technologies and Precision NanoSystems, seeks to assemble three-dimensional, structured brain organoids from human induced pluripotent stem cells for use in pre-clinical screening of hits against neurodegenerative diseases.

The second project seeks to attenuate the disease-carrying capacity of the mosquito to spread disease by targeting its sense of smell. We are engineering the mosquito olfactory cascade into microbial hosts in order to screen behaviour-modifying compounds in a high-throughput manner.

We are also an important player in the nascent organ bioprinting community at the University of British Columbia. Prof. Yadav is one of the lead organizers of the annual ‘Printing the Future of Therapeutics in 3D’ roundtable at UBC. The event draws on leading practitioners from academia, industry and clinics and serves as the premier forum to ideate on technological trends in the field.

Read more: Organ printing holds promise for better healthcare, cheaper drugs

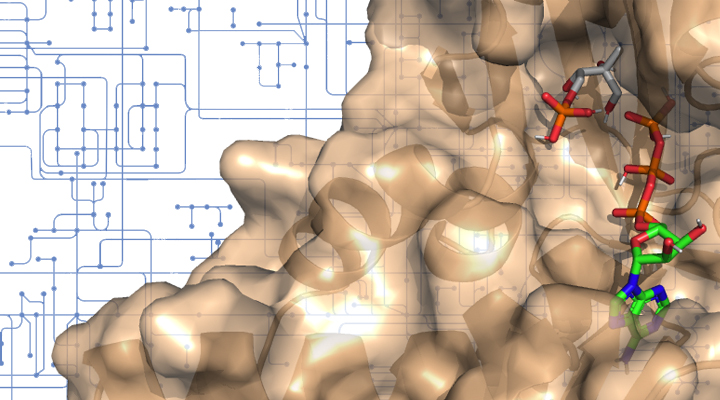

Our industry-connected research program on pharmaceutical product development is advancing a concept that we dub ‘medicine-by-design’, a fast and low-cost methodology to advance a drug molecule from concept to formulated product. The de novo design of a pharmaceutical product for a particular disease commences with computational analyses of protein-protein and gene-gene interactions associated with that disease in order to identify a promising target and a natural product that can bind to it. The molecule is subsequently synthesized in a microbial chassis through the application of metabolic and enzyme engineering. It is then suitably formulated to ensure controlled release at the intended site of action, and we have established a pipeline that facilitates rapid identification, synthesis and testing of formulations.

Our industry-connected research program on pharmaceutical product development is advancing a concept that we dub ‘medicine-by-design’, a fast and low-cost methodology to advance a drug molecule from concept to formulated product. The de novo design of a pharmaceutical product for a particular disease commences with computational analyses of protein-protein and gene-gene interactions associated with that disease in order to identify a promising target and a natural product that can bind to it. The molecule is subsequently synthesized in a microbial chassis through the application of metabolic and enzyme engineering. It is then suitably formulated to ensure controlled release at the intended site of action, and we have established a pipeline that facilitates rapid identification, synthesis and testing of formulations.

We work closely with an industrial partner, InMed Pharmaceuticals. We have already demonstrated the feasibility of our approach through our work on the development of a ‘smart’ contact lens for treating glaucoma and a printable bandage for healing damaged skin in patients suffering from Epidermolysis Bullosa Simplex (EBS). Both projects have led to patent filings and have been advanced to pre-clinical testing.

Read more: Glaucoma treatment could ease symptoms while you sleep

The Government of Alberta estimates the total acreage of oil sands tailings ponds to be as high as 77 square kilometers. Although these ponds provide considerable benefit by promoting water reuse and withholding the release of toxic organic compounds such as naphthenic acids, there is a critical need to rehabilitate the land and treat all remaining water. The key challenge for treating naphthenic acids is the sheer volume of tailing ponds and the dilute, yet highly toxic nature of the contaminants.

The Government of Alberta estimates the total acreage of oil sands tailings ponds to be as high as 77 square kilometers. Although these ponds provide considerable benefit by promoting water reuse and withholding the release of toxic organic compounds such as naphthenic acids, there is a critical need to rehabilitate the land and treat all remaining water. The key challenge for treating naphthenic acids is the sheer volume of tailing ponds and the dilute, yet highly toxic nature of the contaminants.

In partnership with Metabolik Technologies, a company that was spun out from the lab, we are developing an engineered bacterial strain that will harness several genes obtained from microbes that naturally degrade naphthenic acids into less-toxic by-products. The engineered strain will also tolerate and respond to the presence of NAs by expressing a genetic circuit that modulates the biodegradation of NAs, serving as a biocontainment system when NAs are fully remediated. The result is a biological solution that thrives off NAs and increases treatment efficacy without additional input costs, while simultaneously expressing a ‘kill-switch’ to terminate growth once the NA concentration reaches regulated safety levels. This manipulation ensures stimulus-specific biodegradation, achieves biocontainment and obviates the ill effects associated with accidental release of genetically engineered organisms.

Our passive, in-pond biological approach requiring limited infrastructure, allows operators to cost-effectively treat the toxicity and ensure appropriate rehabilitation of the site. The microbial solution is designed to be tightly correlated with naphthenic acid concentration, ensuring no introduction of foreign microbes into the environment.

Read more: Chemical-eating bacteria: A tiny solution for the oil sands' big problem

We actively research and develop mechanisms for translating our work on the development of advanced bioprocesses for the production of value-added molecules to industry, and we achieve this objective through technoeconomic assessments. One of most recent contributions to technoeconomics has been the formulation of a metric that facilitates rapid estimation of profitability of manufacturing processes in the new bioeconomy.

We actively research and develop mechanisms for translating our work on the development of advanced bioprocesses for the production of value-added molecules to industry, and we achieve this objective through technoeconomic assessments. One of most recent contributions to technoeconomics has been the formulation of a metric that facilitates rapid estimation of profitability of manufacturing processes in the new bioeconomy.